Howard Clark 1086 Naginata

Howard Clark has been making Japanese styled sword blades for well over two decades. Originally, he worked with different stock and pattern welded steel that he made, but also pattern welded stock by another American master, Daryl “Grandpa” Meier. Howard settled into his primary materials, 1086, and L6 Champalloy for his sword creations, for reasons of durability. Working with these modern materials pushes the envelope of heat treating and smithing skill as they are completely different animals than traditional Japanese sword steel. Both have a look that are unique unto themselves.

Most of the swords that Howard produces are destined for practitioners who will through the course of their training be quite hard on their swords, much harder than anyone would reasonably wish to push a traditional Japanese crafted sword. However, the collector community also holds Howards work in very high regard. The 1086 stock is effectively the same kind of material from which high speed cutting tools are made.

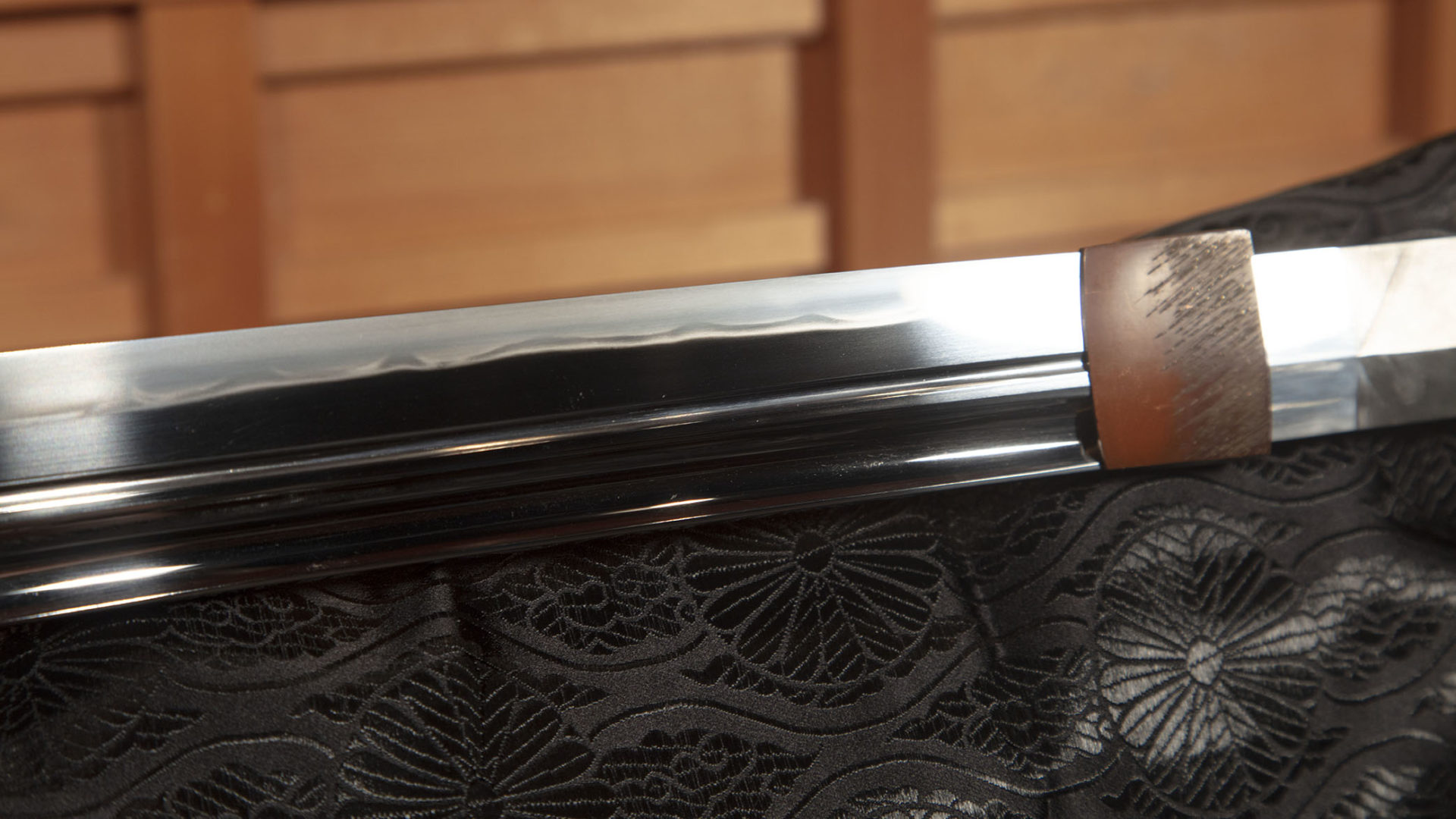

As modern homogenous steel, they do not carry a “hada” or grain pattern as Japanese swords have. They will sometimes exhibit some very small carbide alignment and/or “mill grain” where the rollers express a kind of subtle patterning through default of compression during forming and extrusion. The hamon however is completel Howard’s creation and the 1086 material displays a rather unique form of yakiba. Typically, it is a soft notare with a bright thick habuchi showing nijuba, uchinoki, yo, and some kuichigaiba.

Crafting naginata are difficult and this one is quite frankly, a monster at 26 7/8 inches on the cutting edge. In its shirasaya it is over 5 feet long. I asked Howard how many naginata he had made over the years and in his memory, there were only about 6 or 7. Out of those only two had been carved with Naginatahi and Soebi. I purchased this blade from him while at a show in about 2006 contingent that he install both sets of hi in it. He was reluctant because carving hi into a blade that is made from tool steel requires some effort and cutting tools that will actually do the job, but he did and it adds to the impact and tradition of such an imposing shape.

It was sold to a client and sent to Samuel Rediske for the copper habaki and shirasaya, then the polish completed. It is now back on the market for a new home.

- Nagasa: 68.2 cm (26 7/8”)

- Motohaba: 3.3 cm (1 1/4”)

- Kasane: 7 mm

- Nakago length: 61.4 cm (24 1/8”)

It is inscribed by Howard with his distinctive “O Mimi” (大耳) or “big ear” signature. His smith name is tongue in cheek as he lives in the middle of corn country south of Des Moines, Iowa, and has one ear that is larger than the other, scarred as a result of an accident many years ago. Thus, he is the “big ear in the corn patch.”

SOLD